Fume Extractor Significant

There are three main areas of consideration associated with the fume:

1. Health issues - the effects it may have on the workforce coming into contact with it

2. Laser efficiency - the effects on the laser optics.

3. Product contamination - the effects on the products being lasered

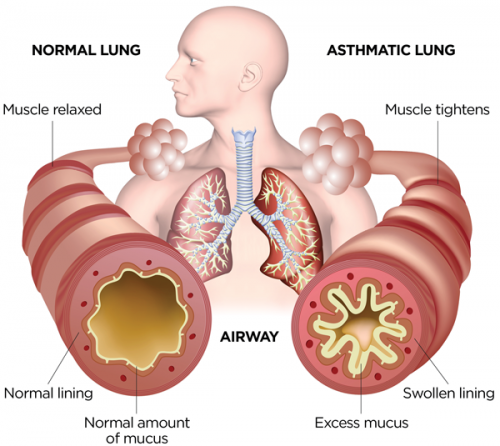

These fumes or particles fall within the respirable range and need to be removed from the working environment to prevent bronchial or lung damage.

Types of Airborne Contaminants

Airborne particulate matter is a combination of solid particles and liquid droplets. Employers have a legal duty to assess any risk to health created by an industrial process and the materials being worked.

Particulate

Dust can also become a substance hazardous to health under COSHH when it is present at concentrations in the air greater than 10 mg/m3 (average over an 8-hour period) of inhalable dust. It can cause serious problem in respiratory disease.

Gas

The gaseous organic compounds produced known as Volatile Organic Compound (VOC). VOC gas tend to be acidic and require special designed media for acid gases is included in the gas filter

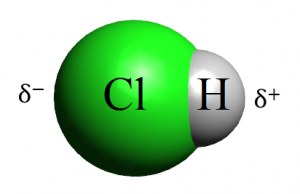

HCL

Lasing PVC is worth a special mention in this context since it releases hydrogen chloride and small amounts of phosgene both of which are extremely toxic.

How Fume Generated in Working Environment

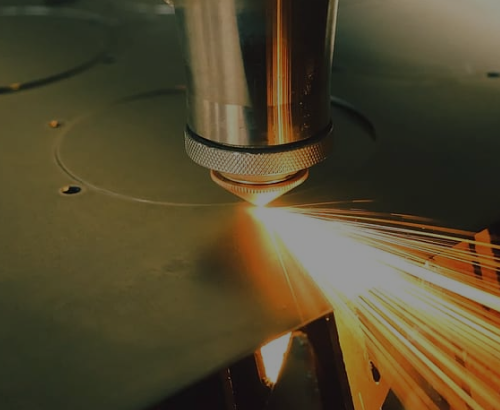

Laser Application

Lasers are now an essential tool in industry for cutting, marking, engraving and welding a vast range of materials. Metals are the most commonly worked substrate but organic materials (plastics, paper, wood) are catching up fast. A variety of toxic fumes and particulates are generated when different substrates are being lasered the majority of which is less than 5µm (microns) in diameter. These contaminates are known within the industry as LGACs (Laser Generated Air Contaminates).

PVC is worth a special mention in this context since it releases hydrogen chloride and small amounts of phosgene both of which are extremely toxic. HCI is classed as a major health hazard, and as a result has a maximum exposure level of 1ppm (Part Per Million) over an eight hour period (from HSE EH40/2000 Occupational Exposure Limits).

Electronic Application

Fume extractor special designed for electronics soldering application that generate fume comprising; resn acid particulate and VOC compounds. Solutions are available for manual and automated processes including: wave solder, reflow, selective solder and conformal coating applications.Exposure to rosin-based solder flux fume (colophony) is one of the most significant causes of occupational asthma, creating the potential for permanent and irreversible impact on health.

BOFA larger volume extraction units have the capacity to be used on all manufacturers of automated soldering systems such as reflow ovens. Large filter capacity and vast carbon filters ensure long filter life and optimum extraction even when lead free solder is used. Adjustable and regulated air flow control ensures consistent temperatures within the solder machine/reflow oven, throughout the life of the filters.

Dental Application

Whoever working in dental laboratory, require to aware of the potential health and safety risks associated with the toxic fumes and particulates that are generated by CAD/CAM manufacturing, monomer mixing and hand finishing processes. It is essential you use an effective dust and fume extraction system to remove these risks from your technicians’ working environment.

BOFA’s DentalPRO range of dust and fume extraction systems effectively removes potentially harmful Zirconia dust and particulate generated during the production of dental implants. The DentalPRO Mono extraction unit is a specialist system to effectively remove Monomer toxic fumes and vapours.

Monomers can potentially causea wide range of adverse health effect from irritation to eyes, skin and mucous membranes through to allergic dermatitis and asthma. Methacrylate(MMA) a widely used monomer in dentistry causes abnormalities or lesions in several organs.

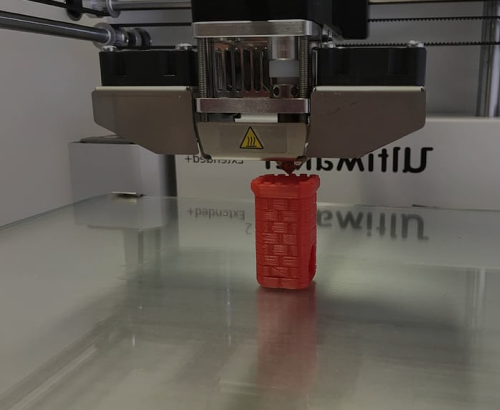

3D Printing Application

3D printing or additive manufacturing, is crate a 3 dimentional object from a CAD drawingwith XYZ robotic software. The material, which can be a range of plastics or metals, is fed to the deposition point usually in wire or powder form where it is heated and fused to the previously deposited material.

Emissions from fused filament printers can include a large number of ultrafine particles and VOCs. The hazardous particles emitted in peak a few minutes after printing started says National Institute for Occupational Safety and Health (NIOSH)

The BOFA 3D PrintPRO range has been designed to capture and filter out harmful airborne toxic gases and particulate from open frame, table-top enclosed / partially enclosed and fully enclosed 3D printers. The filter design includes Health and Safety compliant HEPA grade particulate filter media, which has an efficiency of 99.997% at 0.3μm, and deep bed activated carbon filters to remove organic gases and vapors.

Legislation & Regulation

The potential of harmful airborne emissions in workplace is lightly controlled around the world through legislation and regulation. There are three main covering legislation extraction:

1. Extraction System Safety

All BOFA products comply the standard with the CE marking requirements in Europe. America and Canada generally require equipment to be tested and approved to an appropriate international standard by UL, CSA or other approved test house.

2. Worker Safety

Employers require to have statutory obligation to protect their workers. Extraction equipment to help local exhaust ventilation to capture harmful dusts, fumes or vapors. Legislation is in place to protect worker from exposure harmful fumes and ensure equipment operate correctly.

3. Disposal Hazardous Waste

Disposal of hazardous waste require to take it seriously. The particulate, or fume captured by extraction system may cause the used filters to be classified as hazardous waste. Disposal must be in line with regulatory requirements.

Keep yourself up to date with Latest Legislation

Workplace safety is priority of your health.