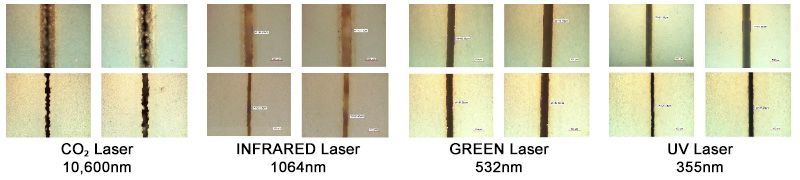

The 532nm green laser within our FALIT ™ and the FALIT Duo™ offers FA labs a longer depth of focus for cross-sectioning thicker parts with the draw-back of having a larger spot size and larger Heat Affected Zone (HAZ) than the UV laser. The green laser has been employed by many semiconductor failure analysis labs for cutting parts out of PCBs where the solder balls, and surrounding components, cannot be damaged. The green laser is also used for cutting electronic components in half as a pre-process to either Focused Ion Beam (FIB) cross-sectioning, or mechanical polishing. Our experience shows that we can get to within about 75-microns from the area of interest without damaging it while using the green laser. As, in most cases, our process for preparing a sample for solder ball adhesion inspection does not melt the solder ball, the FA lab is able to quickly process a sample to further analyze the solder-to-pad adhesion without introduction of external force or heat which might otherwise call into question the inspection results.

With the optional 355nm UV laser within our FALIT ™ and the FALIT Duo™ offers higher precision, a smaller spot size, and a smaller Heat Affected Zone over the green laser. The UV laser is recommended where the failure analysis lab processes, via cross-sectioning or cutting, a wider array of different packages, or when dealing with silicon wafers. Cuts from the UV laser are much more fine which allows more bulk material to be removed in an effort to get closer to the area of interest during cross-sectioning. Silicon wafers can be sliced and diced with up to 10-watts of UV power. As UV is absorbed by most materials, it provides the FA lab with the flexibility to process a wider array of parts.

X Sectioning Gallery

Diamond saws and other mechanical methods of cross-sectioning put physical stress into a part. It is then difficult to determine whether the defect (such as delamination) was already there or caused by the mechanical process itself. Laser cutting presents NO such problem. There is no mechanical force introduced with a laser. Therefore, cross-sections can be made much closer to the actual defect diminishing the polishing time or in many cases eliminating polishing altogether

SCRIBE – DeLid Gallery

Lids and covers over components that need to be analyzed have always been a problem in the Failure Analysis Lab. Mechanical micro routers can damage internal parts, require complicated fixtures, and even destroy samples. With the FALIT™ Laser this process is quick, simple, and successful. A Green laser (532nm), or a UV laser (355nm), can be used to cut the top of a lid completely off.