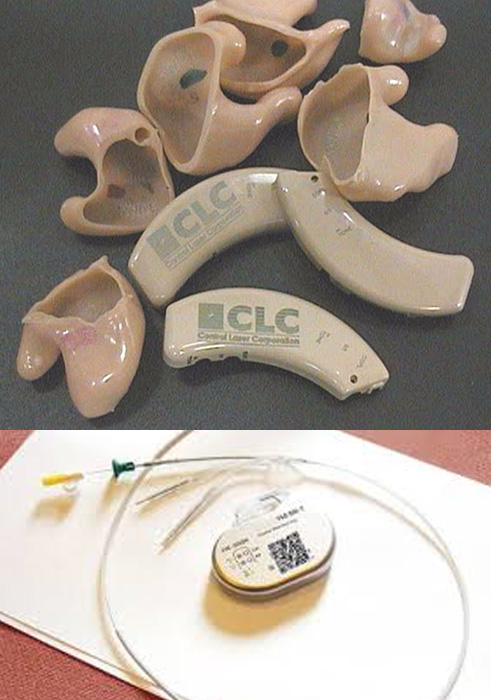

Our principal, Control Laser is a pioneer in being the first laser marking company to fully implement FDA, GS1 and HIBCC® UDI medical marking standards into laser marking systems. CLC Medical UDI-Mark™ systems mark a variety of components and materials with FDA UDI compliant AIDC , GTIN, GLN and HIBC marks.

The materials used in the medical industry include: metals, plastics, composites, ceramics, and more which can be processed with our laser systems. Medical device manufacturers have relied on our compliant systems to provide the traceability requirements of medical marking because we understand these complex rules.

We also have Medical UDI-Mark™ systems for micro-welding and micro-cutting intricate and sensitive parts used in the medical industry.

Our GS1 and HIBCC UDI medical laser marking systems come in a wide variety of wavelengths, power levels and beam profiles which give us the ability to mark any type of material or part.

Traceability is the core purpose for implementing the UDI marking rules since every piece that goes into a human needs to be accounted for. Being able to trace the part back to the source is imperative if there is some complication, but providing a mark that does not create an issue is also very important. Our experience with medical marking allows us to understand this application and assist our customers in providing proven UDI laser marking systems. Over 50-years of service and we are still the leading laser company for medical laser marking.

Our plasma range of microwave and radio-frequency assisted drying equipment. This equipment associates microwave power with hot air, steam or vacuum, for excellent drying performance in diverse applications such as drying of pharmaceutical products, enzyme products, biopharmaceutical powders, ceramics, polymers etc..