Type of Fume Extraction System in Electronics: (A) Tip (‘T’) extraction, for high pressure/ low airflow soldering processes

TVT 2

The TVT 2’s high vacuum extracts and filters fumes and debris through small bore hoses and attachments. Ideally suited for soldering iron tip extraction, vac pens and any application requiring close proximity, such as microextraction.

T 1

Single operator high vacuum extraction system for hand solder applications. Designed specifically for portability and extremely low noise levels. The T 1 extracts and filters fumes and debris through small bore hoses and attachments.

T 15

Mid-range high vacuum fume extraction system with a built in silencer for low noise levels. With its three-stage filtration and filter warning indicator, this is a true industry favorite, suitable for 5-15 operators. The T 15 extracts and filters fumes and debris through small bore hoses and attachments

T 30A

The T 30A is the most advanced system in our range of high vacuum units. With a built in silencer, for low noise levels, a large carbon filter and a filter warning indicator this is a true industry favourite. It is ideally suited to hand soldering iron tip extraction, protecting up to 30 operators with its automatic airflow control and three-stage filtration process.

T 60

The T 60 high vacuum unit is designed to extract and filter fumes and debris through small bore hoses and attachments. Due to the high concentration of debris generated from up to 60 operators, this system has been designed to keep the unit compact, but still utilise a comprehensive filter system.

Type of Fume Extraction System in Electronics: (B) Volume (‘V’) for low

pressure/ high airflow electronics processes.

V 200

The V 200 is a single arm, portable solder fume extraction system that comes complete with an extraction arm and installation kit containing everything required to set up an operator with ease. The low noise level and fully comprehensive three-stage filtration

is ideal for factories with changing production demands.

V 250

The V 250 is a dual arm, portable solder fume extraction system that comes complete with two extraction arms and installation kits containing everything required to set up two operators with

ease. Minimal installation allows this unit to be moved with the work bench when factory layouts need changing due to production requirements.

V 300E

Entry level arm fume extraction for solder applications. This compact, low cost system is capable of generating high airflow rates from a range of bench top attachments, including larger hoses. This fume extraction unit can be positioned comfortably under a bench with a simple installation kit to connect to the most suitable extraction accessory.

V Oracle iQ

This advanced high volume tip extractor combines a powerful range of features into one unit. This versatile unit can be used across a range of electronics applications and the revolutionary auto-voltage sensing blower automatically self adjusts to run on any voltage worldwide.

V 2000 iQ

The V 2000 iQ’s technology delivers superior and measurable performance, ensuring airflow and filtration is maintained even when particulates start to build up. The dual filter system creates maximum capacity while the three-stage filtration process ensures peak performance. It’s user friendly too, with a design that makes easy work of filter changes

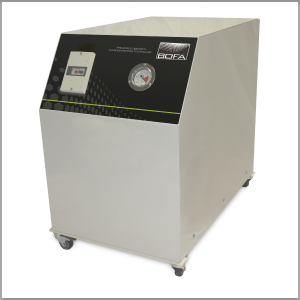

V 4000

BOFA’s V 4000 volume fume extraction system has the capacity to be used on all manufacturers of automated soldering systems such as reflow ovens. Large filter capacity and vast carbon filters ensure long filter life and optimum extraction even when lead free solder is used.

V Oracle SA iQ

The most technically advanced global solution for high volume arm solder fume extraction. The V Oracle SA iQ has been enhanced with BOFA’s iQ Operating System and incorporates a powerful range of unique features into one compact unit.

ILF 300/600

The BOFA inline pre filters have been designed specifically for applications that generate high amounts of dust or particulate. The filter unit is positioned alongside the main BOFA fume filtration system to increase the overall filter capacity and extend the life of the main, more expensive filters.

Spark Arrestor 2

BOFA’s Spark Arrestor 2 unit effectively prevents potentially damaging burning particulates. Hot burning particulate is transported through the specially designed plates positioned within the airflow, slowing the burning particulate down until it finally drops into the removeable drop-out chamber, so protecting the fume extractor.

FireBOX GA+/MA+ self-extinguishing inline pre filter

In the rare event that a burning ember is drawn into the fume extraction unit, there is the possibility that debris in the filters could ignite. Although any resultant fire would typically be retained within the fume extraction unit, this would cause significant damage.