FIT and FORGET service free Technology

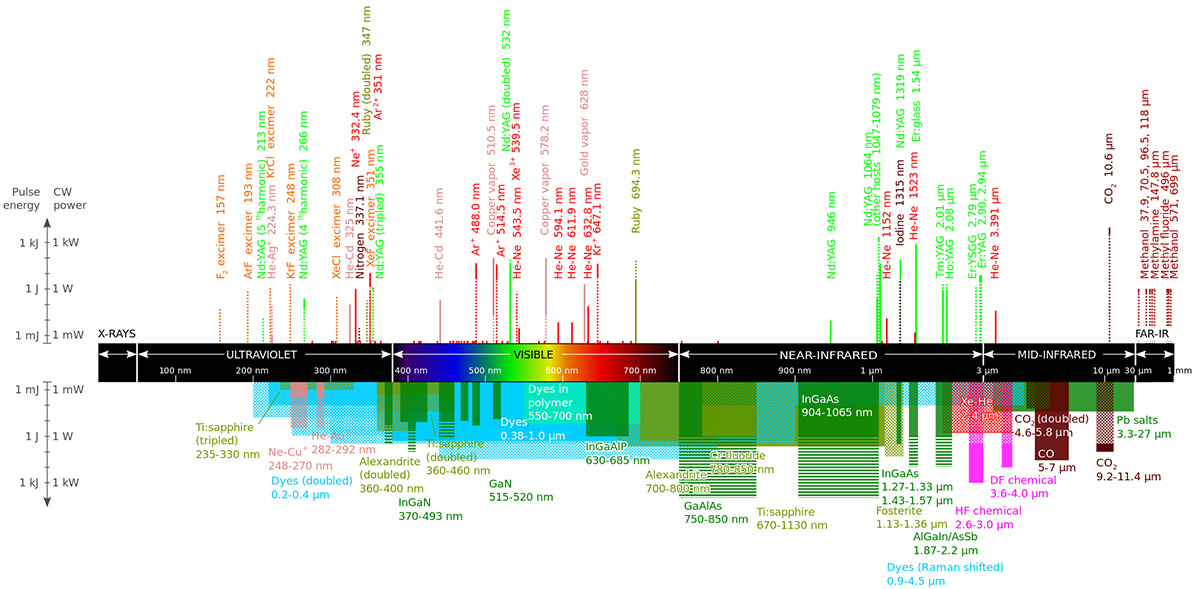

LASER WAVELENGTH and APPLCATIONS

CO₂ Laser Tools

CLC next generation CO₂ lasers are an economical and versatile solution for laser engraving on organic materials Carbon Dioxide gas Laser (10,600nm) have unique marking characteristics because they can process many base materials that other wavelengths are incapable of marking successfully.

CO₂ lasers are also top choice for the ON-THE-FLY marking or engraving Applications for the packaging industry that require very high speed Processing.

Alphanumeric, graphics and bar-codes can be marked up to 1,250 characters per seconds.

- This engraver tool uses a beam of laser light as the engraver tool, so no part of the machinery actually touches the material being engraved.

- Crisp, clear marks on plastic, paper, cardboard, glass, acrylic, leather, wood and other organic materials.

- Effective laser cutting at higher power levels on anodized aluminum and mild steel applications.

- The engraving quality is unmatched for reproducing graphics or organic materials.

Laser-able Materials:

Some of the few material our CO₂ laser tools can process

| MATERIAL | ENGRAVE | CUT |

| Wood | ||

| Acrylic | ||

| Fabric | ||

| Glass | ||

| Semiconductor Devices | ||

| Semiconductor Die / Wafer | ||

| Bare Metals | ||

| Ceramic | ||

| Plastic | ||

| Fiberglass | ||

| Painted/Coated Metals | ||

| Anodized Aluminum |

Infrared Laser Marking and Engraving Machine

CLC ProWriter™ F-Series & S-Series fiber laser markers and engravers are our most widely used systems, capable of quickly and efficiently processing a wide range of application types & materials with varying wavelengths and power levels. While prominently used for marking and engraving, our fiber lasers also excel at cutting various materials at high power.

Aside from precise marking and engraving quality, these machines are basically maintenance-free with no need for external water chillers (100W&under), lamp changes or other tedious and costly upkeep, which was common with the older laser engraving machines. The long expected lifespan of CLC fiber lasers will ensure your continued, stress free production for years to come

- Marks and engraves the widest range of materials including Titanium, Ceramics, SST, Aluminum and some type of plastics.

- Low-Cost, Compact and Versatile.

- Zero consumables and minimal maintenance.

- Easy-To-Integrate – Small 19” rack mount footprint provides for an easy fit into assembly lines or other equipment's, in any orientations.

IDEAL FOR BOTH LARGER INDUSTRIAL APPLICATION AND SMALLER SCALE JOBS

Laser-able Materials:

Some of the few material our Infrared laser tools can process

| MATERIAL | ENGRAVE | CUT |

| Wood | ||

| Acrylic | ||

| Fabric | ||

| Glass | ||

| Bare Metals | ||

| Semiconductor Devices | ||

| Semiconductor Die / Wafer | ||

| Ceramic | ||

| Plastic | ||

| Paper | ||

| Fiberglass | ||

| Painted/Coated Metals | ||

| Anodized Aluminum |

GREEN Laser Machine

CLC Draco™ green laser machines are the perfect solution for cutting, engraving, X-sectioning and marking a wide array of metallic and ceramic materials.

With a TEM₀₀ laser beam, and wavelength of 532nm, a spot size around 30 µ can be achieved, or less depending on the lens configuration.

- Cut or engrave thin metals, ceramics, semiconductor devices, semiconductor wafers ( silicon, GaAs), fiberglass, carbon composites and more with minimum heat imparted.

- 5Watts to 25 Watts available

- Incredible edge quality

MOST CUSTOMER PREFERRED LASER MACHINE FOR ENGRAVING MICRO-MACHINE THIN METALS, FIBERGLASS, CERAMICS, SEMICONDUCTOR, CARBON COMPOSITES.

Laser-able Materials:

Some of the few material our GREEN 532nm laser tools can process

| MATERIAL | ENGRAVE | CUT |

| Wood | ||

| Acrylic | ||

| Fabric | ||

| Glass | ||

| Semiconductor Devices | ||

| Semiconductor Die / Wafer | ||

| Bare Metals | ||

| Ceramic | ||

| Plastic | ||

| Paper | ||

| Fiberglass | ||

| Painted/Coated Metals | ||

| Anodized Aluminum |

UV Laser Machine

CLC Draco™ UV laser’s short wavelength (355nm) allows for incredibly small yet precise laser markings, engravings and details micro-machining applications. The beam produced in the UV spectrum is also capable of various non-thermal, photochemical, laser interactions or “COLD” processing.

- Precise quality and short cycle times.

- Ideal for “STERILE” marking for medical industry

- Capable of marking and engraving sensitive material such as glass, plastics and ceramics.

- High contrast and efficient

Laser-able Materials:

Some of the few material our UV laser tools can process

| MATERIAL | ENGRAVE | CUT |

| Wood | ||

| Acrylic | ||

| Fabric | ||

| Glass | ||

| Semiconductor Devices | ||

| Semiconductor Die / Wafer | ||

| Bare Metals | ||

| Ceramic | ||

| Plastic | ||

| Paper | ||

| Fiberglass | ||

| Painted/Coated Metals | ||

| Anodized Aluminum |